Replacing the Paddles on Your Log Washer

Coarse material products that are out of spec, such as those that are laden with silt and/or clay, are not desirable in the aggregates industry. Therefore, aggregates producers rely on the heavy-duty scrubbing capabilities of log washers to remove these deleterious materials as part of their wet processing system.

Log washers are designed to remove insoluble clays, plastic/oily clays, cemented stones, conglomerates and slimes from coarse material feeds that are too difficult to break up in screw washers. These machines thoroughly break down, scour and clean even the toughest materials, including natural and crushed gravel, crushed stone and ore.

Although Log washers are built tough to handle rough material, even they can use a little TLC every now and again, especially if that care means your operation will run more efficiently. Take care to screen out oversize material that can harm log washers, as well as finer material, like sand, that cushions the washing action.

Replacing the paddles on your log washer when they wear down is another way to keep your log washer running efficiently and your product meeting specifications. It also ensures your log washer is providing the maximum amount of scrubbing to give you a cleaner end product.

How Do You Know If the Paddles on Your Log Washer Need Replaced?

The paddles on a log washer act as the scrubbing agent, and as such, they see the most impact with the coarse material being washed. As feed material and water enter the feed end and the solids settle to the bottom of the tub, the intermeshing paddles on the log washers’ two rotating shafts violently work the settled solids, grinding and abrading the material to provide total area scrubbing. The paddles also feature a corrugated surface that forces harder stones to break down softer deleterious materials.

Paddles on an Eagle Iron Works Log Washer are corrugated to force harder stones to break down softer materials.

The leading edge of the paddles are square in shape, which helps to break down the material. You’ll know the paddles need replaced when the square leading edge begins to round out due to constant contact with the aggregate material. Rounded paddles don’t have as much interaction with the rock and therefore don’t clean the material as well.

Your quality control testing will notify you that the rock coming out of your log washer isn’t as clean, if there is too much clay dust on the rock, or if it is out of spec. When this happens, you’ll want to either swap or replace the paddles to ensure the rock undergoes maximum scrubbing.

Swapping the Paddles

The leading edge on the inside of a paddle will be the first to wear down, as that is the side that has the most impact with the material. Fortunately, the paddles on the right shaft can be swapped with the paddles on the left shaft to extend the life of the paddles.

The right shaft and left shaft can be identified by standing at the drive end of the log washer. The log shaft on the right hand side is the right shaft, and the log shaft on the left hand side is the left shaft. The right shaft rotates clockwise, while the left shaft rotates counter-clockwise.

Swapping the paddles simply switches the paddles on the right shaft to the left shaft, and vice versa, so both square leading edges of the paddles are being utilized. This process doubles the life of your paddles, allowing you to get twice the amount of wear out of your paddles and saving you money in the process.

How to Swap the Paddles

Before you swap the paddles on the log shafts, be sure you have read the log washer manual in its entirety. Be sure to follow your site’s specific safety procedures before beginning any maintenance to your log washer. Failure to do so could result in injury or death.

What You’ll Need

- Corresponding wrench and socket set

- Impact driver

The Process

- Before swapping the paddles on your log washer, ensure the machine is free of material by performing your site’s standard cleanout procedure.

- Then, lockout/tagout/blockout the machine by switching off the power to the log washer and locking the switch in the off position to ensure no power can reach the log washer while you are swapping the shafts. Attempt to start the log washer after it has been de-energized to confirm that the log washer will not start moving once you begin swapping the shafts. Again, you'll want to be sure you're following all safety procedures established by your site before swapping the paddles on your log washer.

- To swap the paddles, unbolt and remove a paddle on the right shaft.

- Then, unbolt and remove the corresponding paddle on the left shaft, and bolt it to the right shaft.

- Bolt the paddle you removed from the right shaft to the left shaft.

- Repeat the process for the remaining paddles in the row.

- Once you’ve swapped a row of paddles on both shafts, you’ll need to rotate the shafts to access the remaining paddles on the three additional rows. You can either turn the shafts by hand, or you can remove the lock from the power switch, restore power to the log washer and jog the shafts into position. Make sure to stay clear of the machine while it is running, and remember to power down the log washer once the shafts are in position and to reapply the lockout/tagout/blockout to the machine. After it has been de-energized, try to start the log washer. Again, this just ensures the shafts will not start turning while you are swapping the paddles.

- Repeat steps 3-7 for the paddles on the remaining rows.

- When complete, remove the lockout/tagout and restore power to the log washer.

Replacing the Paddles

If you’ve already swapped the paddles on your log washer and now the leading edges of the paddles are rounded on both sides, causing the paddles to resemble an airplane or boat propeller, you’ll need to replace them.

Worn paddles on a log washer will become rounded, resembling an airplane or boat propeller.

How to Replace the Paddles

As stated above with swapping the paddles on the shafts, you’ll need to read the log washer manual before replacing the paddles. You should also be sure to follow your site’s specific safety procedures while performing any maintenance to your log washer. Failure to do so could result in injury or death.

What You’ll Need

- Replacement paddles

- Corresponding wrench and socket set

- Impact driver

The Process

- First, perform your site’s standard cleanout procedure to ensure the log washer is free of material.

- After the log washer has been cleaned of material, lockout/tagout/blockout the machine by switching off the power to the log washer and locking the switch in the off position to ensure no power can reach the log washer while you are replacing the paddles. Attempt to start the log washer after it has been de-energized to confirm that the log washer will not start moving once you begin replacing the paddles. Be sure to follow the safety procedures your site has established.

- Replace the paddles one at a time, starting at the bottom and moving up the shaft, by removing the bolts from the old paddles, removing the old paddles, installing new paddles and bolting those paddles to the recommended torque specifications.

- After you’ve replaced a whole row of paddles, you can either turn the shaft by hand so the remaining rows can be accessed easier, or you can remove the lock from the off switch, restore power to the log washer and jog the machine to position the remaining rows of paddles. If you employ the latter option, be sure to stay clear of the machine while it is running and to reapply the lockout/tagout/blockout once the shafts are in position. Again, attempt to start the log washer after turning it off to confirm it will not start moving as you are replacing the paddles.

- Repeat the process of removing and replacing the paddles on the remaining rows.

- When you’ve replaced all of the paddles on your log washer, remove the lock and restore power to the machine.

Replacing the worn paddles on your log washer will enable the machine to continue to break down deleterious materials and to provide the maximum amount of scrubbing.

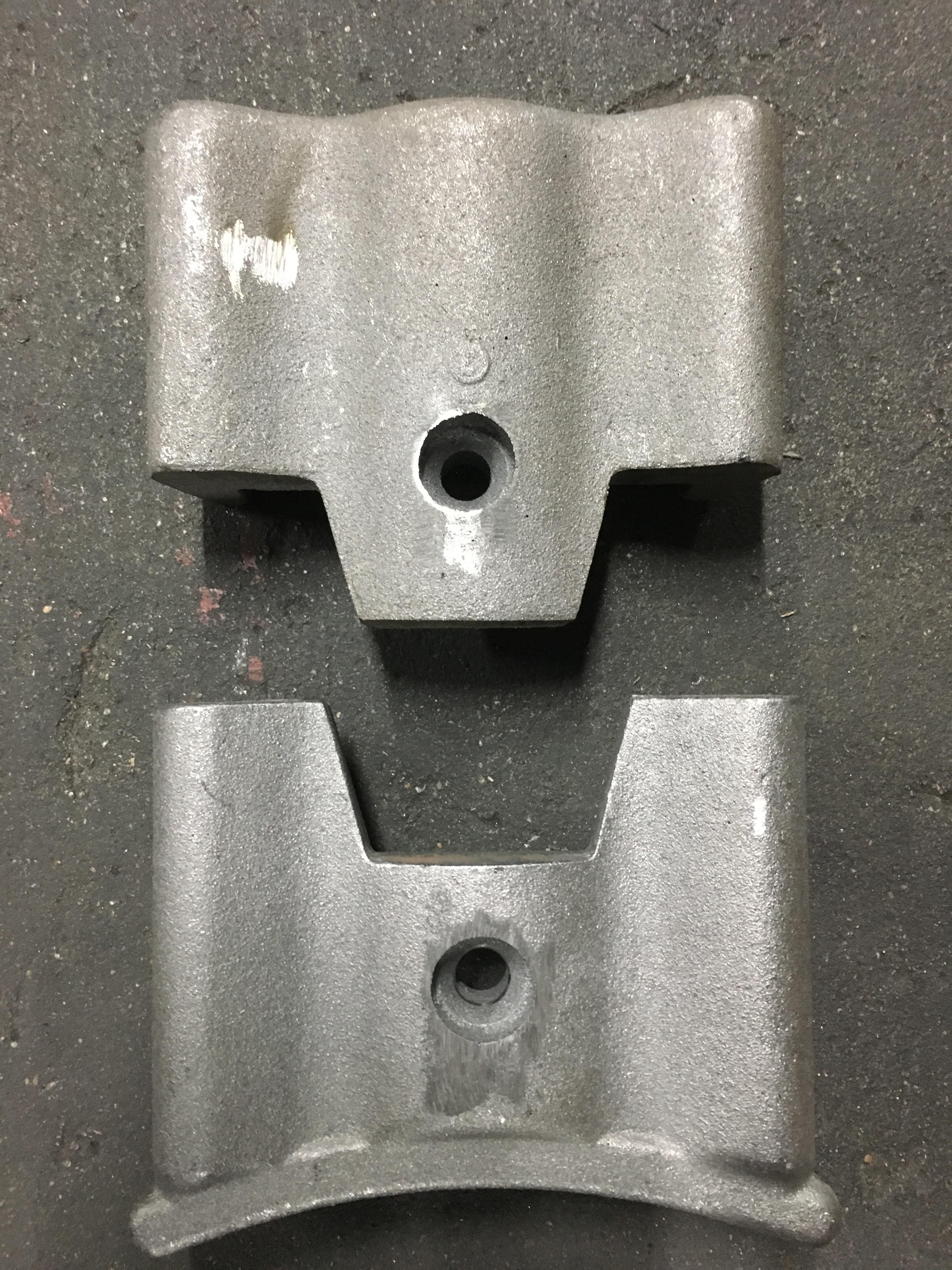

Eagle Iron Works offers a two-piece paddle option for most of their log washer models, which are known for their exceptional scrubbing action. The two-piece design gives you an economical replacement option. Eagle also offers one-piece paddles, which work well with large sized feed up to 4” square. Both the two-piece paddles and one-piece paddles are oversized to provide the maximum amount of rock-on-rock scrubbing and a high level of force against softer materials. Eagle paddles also feature a wrap-around design to protect the paddle support.

Plus, Eagle Iron Works paddles are American designed and manufactured in the USA!

Eagle’s two-piece paddles provide an economical replacement option.

Eagle also offers a one-piece paddle design.

Contact Eagle Iron Works or call +1 515-243-1123 to order your log washer replacement paddles so your coarse material can continue to meet the specifications your operation requires.

Don’t miss a future post about Eagle Iron Works! Subscribe to learn what Eagle Iron Works equipment can do for you!