How To Make Money with EIW Sol-Clay Washers

When aggregates are liberated from the earth, they can contain clay and other deleterious materials that can be harmful to the end product. For example, in concrete applications, clay can cause bonding issues between the aggregate and the cement and negatively affect the concrete’s overall strength. In road applications, clay can prevent water drainage.

Because of the potential problems clay can cause, producers must wash or scrub their aggregate to meet the specifications required for the material’s end use. This is often achieved with Coarse Material Washers, Log Washers or Eagle Iron Works’ Sol-Clay Washer, which falls between the Coarse Material Washer and Log Washer in terms of scrubbing capabilities and is extremely effective in removing soluble clays from aggregate material.

While the Sol-Clay Washer is designed to liberate soluble clays from aggregate feeds, you can make money with your Sol-Clay Washer by maximizing the amount of saleable material you produce from a single feed. More saleable material means more money in your pocket at the end of the day.

Making money from the get-go

You can begin making money with your Sol-Clay Washer right from the start by following the standard installation instructions that come with your machine. These will include essential information for setting up your Sol-Clay Washer to ensure proper operation. The instructions will include information on proper machine elevation and motor rotation, the importance of water and proper feed technique, and initial lubrication guidelines.

Elevation

The elevation of your Sol-Clay Washer plays a large role not only in cleaning the product, but in the amount of product you can wash per hour. To achieve the cleanest product and the highest throughput, ensure your Sol-Clay Washer is elevated to the appropriate level. The Sol-Clay Washer should be elevated at 5 to 10.5 degrees. Five degrees allows the maximum tons per hour of product to be processed, and 10.5 degrees allows maximum cleaning of the product.

Motor rotation

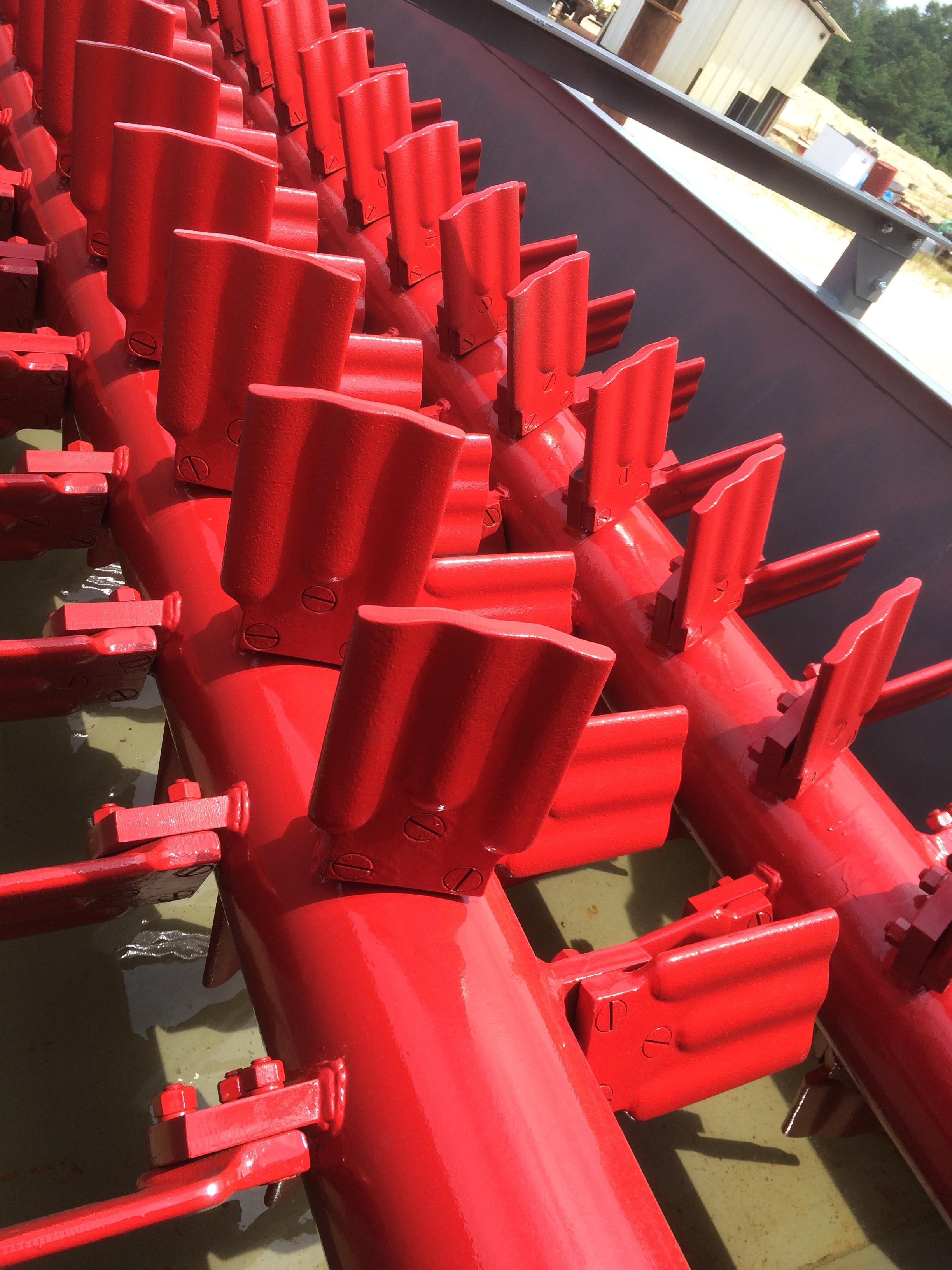

Each Sol-Clay Washer comes equipped with two shafts lined with intermeshing corrugated paddles the entire length. These paddles provide the scrubbing action needed to remove the soluble clays from the material, while the shafts convey the material toward the discharge end. In order to do this, both shafts must be rotating toward the center of the Sol-Clay Washer so that the material can be transported to the discharge end. You can ensure the rotation of the shafts by checking the motor rotation.

Eagle Iron Works Sol-Clay Washers feature two shafts that move the material from the feed end to the discharge end of the washer tub. Intermeshing corrugated paddles on the shafts scrub the material to remove the clays.

Water

The addition of water into the Sol-Clay Washer helps remove the slimes and fines not wanted in the end product. Making sure to add the appropriate amount of water can aid creating in a cleaner product. When installing your Sol-Clay Washer, allow water to be piped to the lower end of the vessel.

Some Sol-Clay Washers feature Hydrotex bearings. These are water lubricated and require potable water – water that is suitable for drinking – to operate.

Lubrication

Eagle Iron Works Sol-Clay Washers are shipped without oil in the gear reducers. These should be filled with a premium quality lubricating oil that contains rust and oxidation inhibitors. Be sure to select an oil with a viscosity that suits the ambient operating temperatures of your local climate. For example, if you are operating in temperatures of 20-70°F, you’ll want to use an oil with an ISO Viscosity Grade of 220 or American Gear Manufacturers Association (AGMA) No. 5EP. If you are operating your Sol-Clay Washer in temperatures over 70°F, you’ll want an oil with an ISO Viscosity Grade of 320 or AGMA No. 6EP. Chevron, Exxon, Mobil, Phillips 66 Co., Shell and Texaco all manufacture products that can be used in Sol-Clay Washer gear reducers.

When it comes time to change the oil in the gear reducer, make sure you use only one name brand for the complete fill so that you don’t have to worry about the compatibility of the oil base stock or additive package.

Feed

Consider screening the material before it enters the Sol-Clay Washer to eliminate all material that is minus ¼”. This will help you obtain optimal results with your material washing.

Eagle Iron Works offers four sizes of Sol-Clay Washers: 24” x 18’, 36” x 25’, 36” x 30’ and 38” x 30’. The 36” machines are designed to process a 1-1/2” top size material and can process a small percentage of 2-1/2” material; however, capacity will be reduced and maintenance may increase. Consider pre-screening the material to eliminate oversize as well.

Keeping the money coming

To continue maximizing the amount of clean product you produce, it is a good idea to inspect your machine daily and conduct weekly, monthly, quarterly, and yearly inspections in addition to the daily ones. Following a maintenance schedule can help you avoid unexpected downtime, which can result in lost profits and costly repairs that can eat up both time and money. Be sure to follow all lockout/tagout/blockout procedures, as well as your site’s safety procedures, before performing any inspections or maintenance.

Daily inspections should take place once per shift. These include:

- Lubricating the Hydrotex bearings. Water should be run through the bearings at all times during operation at 15 lbs of pressure and 25 gallons per minute. To ensure they are thoroughly flushed both before and after operation, allow the water to run through the bearings for several minutes before turning on the power to the Sol-Clay Washer and for several minutes after turning the power off.

- Inspecting the inside and bottom of the tub and removing any material that may interfere with the Sol-Clay Washer’s performance

- Inspecting the reducers, bearings and motors for excessive heat

- Inspecting the electrical cables and connections for damage

- Inspecting the water lines and connections for damage or leaks

- Making sure the side drain board is on and functioning

- Inspecting all belts for proper tension and alignment

- Checking paddle bolts to ensure they haven’t come loose

Weekly inspections should include:

- Inspecting all motor bolts for tightness

- Inspecting the area around the motor cooling fins for cleanliness

- Inspecting for loose bolts

- Checking the outboard bearing vent opening relief slot for evidence of water leakage caused primarily by a leaky shaft seal

- Checking the gear reducer oil level and checking all seals for signs of leakage. When the machine is not running, the oil level in the gear reducer should be at the pipe plug opening on the front of the gear case. If you need to add oil to the reducer, fill it through the pipe nipple that is exposed when the breather cap is removed. The oil level should be checked frequently and regularly. Add oil to maintain the operating level.

Monthly inspections should include:

- Checking the level of oil in the gear reducer and inspecting the breather for cleanliness

- Inspecting all mounting spuds and paddles for operating condition and wear. For paddle replacement instructions, refer to the Replacing Worn Paddles section below.

- Checking the overflow weir for out-of-level conditions

- Inspecting the Hydrotex bearings, if your Sol-Clay Washer has them, for signs of wear and removing any accumulated silt or grit. If the bearing shows ¼” or more of wear, it should be rotated 180 degrees. After this rotation, the bearing must be replaced. If the steel wear sleeve shows 1/8” or more of wear, it must be replaced.

Quarterly inspections should include:

- Lubricating the outboard bearings. More frequent lubrication may be required depending on your specific operating conditions, including but not limited to high moisture levels or an extremely dirty environment.

Six month inspections should include:

- Checking the drive reducer oil

Yearly inspections should include:

- Changing the oil in the drive reducer (replace the oil after 2,000 hours if that comes first)

- Inspecting the condition and wear of the tub and sides.

Click the button below to download the full maintenance checklist for your Eagle Iron Works Sol-Clay Washer.

Replacing Worn Paddles

If during your monthly inspection — or at any time, really — you notice the paddles on your Sol-Clay Washer are beginning to wear, you’ll want to replace them. Sol-Clay Washer paddles have square leading edges, which help to break down the clays and ensure the discharged aggregate is free of deleterious materials.

Because the paddles see so much interaction with the material, the leading edges will begin to round off over time. Worn paddles resemble a boat or airplane propeller. When this happens, replacing the paddles will ensure you are making the most of your Sol-Clay Washer, which can translate into cash in your pocket.

Before replacing the paddles on your Sol-Clay Washer, you need to read the Installation, Operation and Maintenance manual, follow the appropriate lockout/tagout/blockout procedures, and read and follow all safety tags, as failure to do so could result in injury or death.

Needed Materials

- Replacement paddles

- Impact driver

- Wrench and socket set

Instructions

- Remove any material from the Sol-Clay Washer by performing your site’s cleanout procedure.

- De-energize the Sol-Clay Washer by switching off the power and locking the switch in the off position. Try to start the Sol-Clay Washer to be sure that the shafts won’t begin turning once you commence the paddle replacement.

- One by one, remove the bolts from the worn paddles on the top of the shafts and bolt the new paddles to the mounting spuds.

- To access the remaining three rows of paddles on each shaft, you can turn the shafts by hand so that another row of worn paddles is visible. You can also remove the lock from the power switch, power up the Sol-Clay Washer and jog it until another row of worn paddles is visible. If you decide to turn the shafts electrically, first be sure everyone is clear of the machine before removing the lock from the power switch. Once you’ve rotated the shaft, turn off the machine and reattach the locks. Make sure you try to start the Sol-Clay Washer so you can be sure it will not move as you replace the paddles.

- Repeat steps 3 and 4 until all the paddles are replaced.

- When you are finished, you can remove the lock from the power switch and restore power to your Sol-Clay Washer.

Following these maintenance tips will ensure your Sol-Clay Washer is producing the cleanest aggregate and making you the most money.

Don’t miss a future post about Eagle Iron Works! Subscribe to learn what Eagle Iron Works equipment can do for you!